AXFIL work

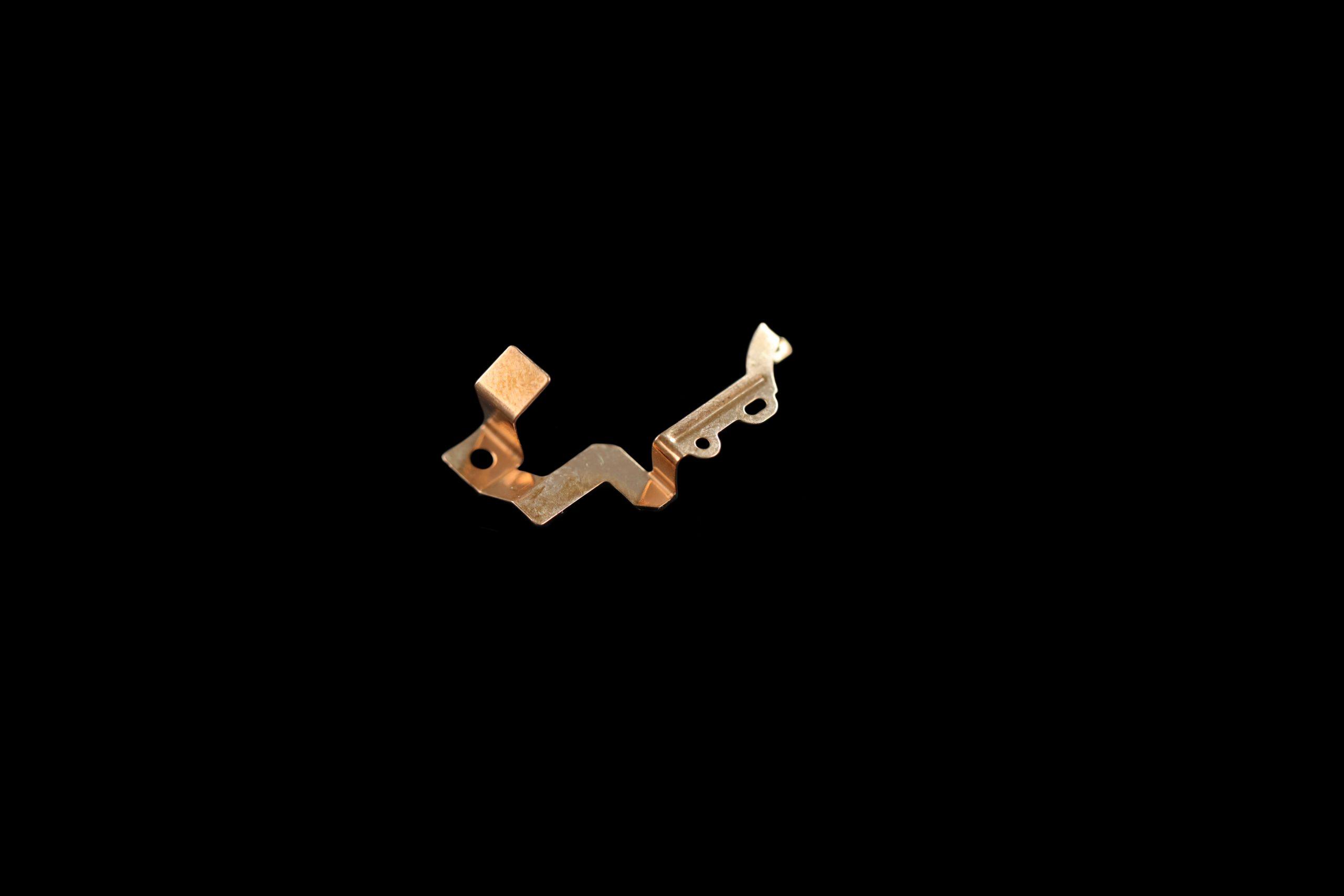

Electrical contact

Function

Electrical contact for crimping, for use with electronic cards

Technical requirements

This electrical contact is designed for an electronic card application for use in aeronautics. Precision manufacturing is essential for our customer, who uses a crimping machine especially adapted for this part. Axfil has the range of technical expertise needed to produce complex parts with 3D geometry in large-sized batches at a reasonable cost, while guaranteeing a high level of precision (±0.02mm) and excellent repeatability. The beryllium copper strip (thickness of 0.25 mm ±15 µm) is formed at high output over several stages: trimming the flat form (±0.02 mm), drawing the central groove and making the holes and oblongs, followed by nine successive folds (±1°) to produce the final form. Particular attention is paid to ejecting the part to avoid any deformation. Statistical controls using a 3D Keyence profile projector help us to quickly detect any deviation associated with the material or wear of the tool, to remove any batches that are at risk. The final packaging was studied closely with the customer to protect the part’s geometry throughout the logistics chain and up to its installation on the customer’s machines.

Materials

Copper Alloy CuBe2