AXFIL work

Electrical connector

Function

Connector overmoulded in a plastic part for electrical transmission

Technical requirements

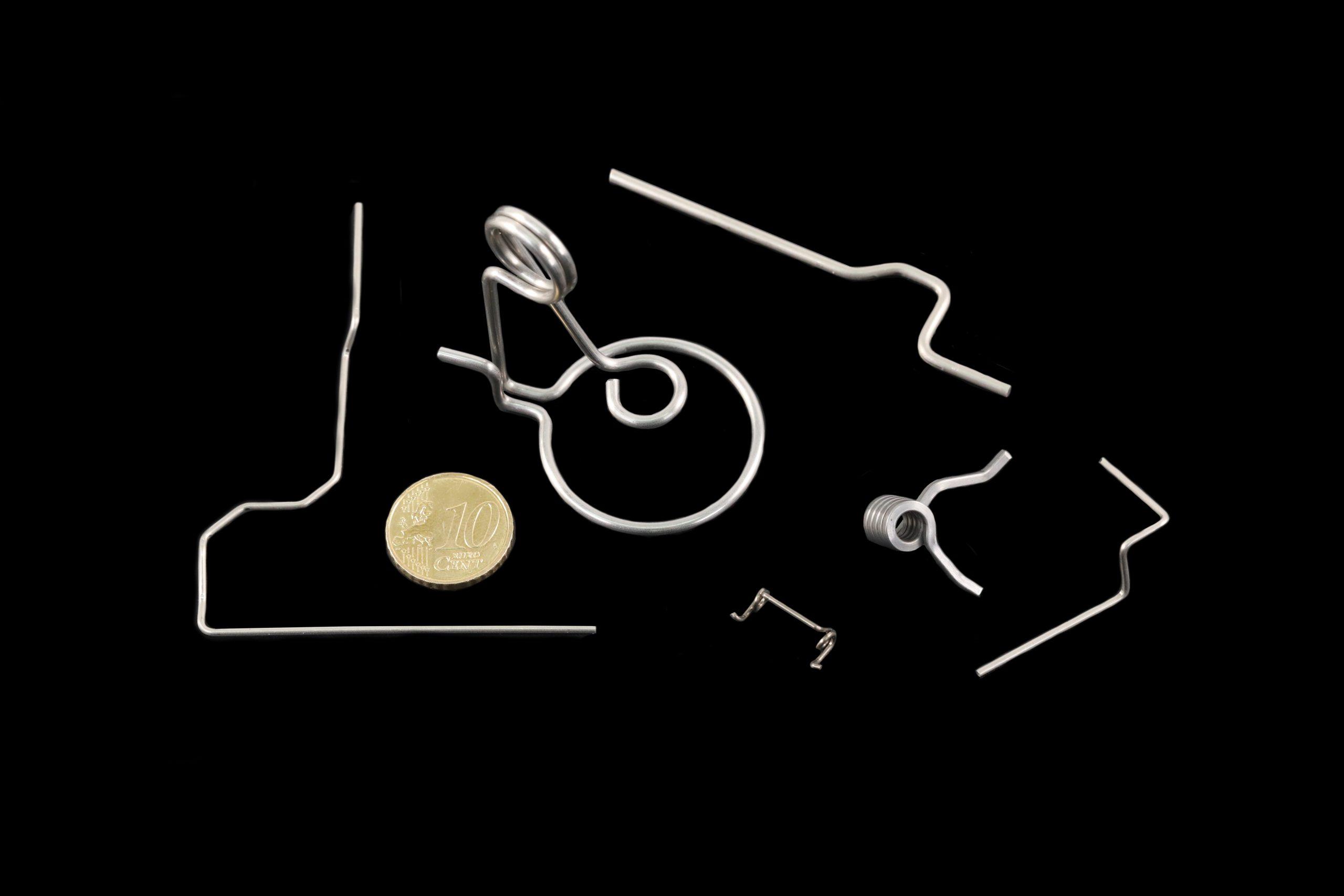

Multiple precision bending Most electrical connectors have several conductive cores moulded together to form a complete unit. We custom make round, square and rectangular conductive tracks.

Depending on the customer’s needs, we also offer stamping, pyramidal ends, die-forged grooves, etc.

The parts usually undergo a substantial series of bending, during which time the angular dispersions (±0.5°) and dimensional dispersions (±0.30 mm) must also be closely controlled. Axfil has all the knowledge and expertise needed to design and maintain tooling to ensure the conformity of parts produced.

Their applications are many: automotive, aeronautics, rail, agricultural mechanisation, energy storage, satellites, construction, capital goods, etc.

Materials

Nickel 99.2% / 2.4066