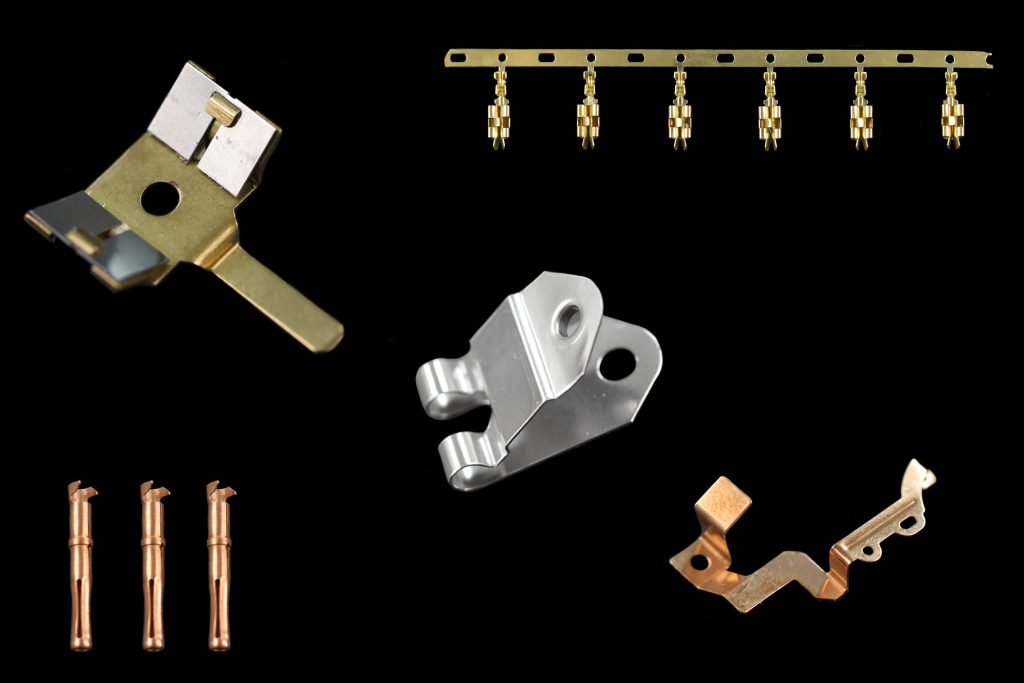

Wire parts and metal strips

Metal strip parts

Wire parts and metal strips

Metal strip parts

Drawing on its long-standing knowledge and expertise in manufacturing metal wire precision parts, Axfil has applied these skills to metal strip machining, achieving the same high standards.

We have developed our own forming machinery to ensure a perfect match between machine and tooling and to manage the entire production line. Tooling for complex parts requires around 100 to 250 mobile parts and settings on average, all of which are adjusted to within 1/100th of a millimetre.

This means we can produce the simplest and most complex forms at the lowest cost, while still meeting your most demanding specifications.

Cutting

Cutting is the first stage in the process of forming a metal strip part. High-quality cutting (precision, flatness, no burring or marking, etc.) is essential to ensure the correct alignment of parts in the tooling machines during subsequent stages and to ensure the precision of the end product.

Drawing

Drawing is used to shape a part, by deforming it between a die and punch. This process requires expert precision tooling and alignment of the parts at every stage of the process, delivering high rates of output at a competitive cost.

Drawing, unlike machining or casting, has the technical advantage of reinforcing the mechanical fatigue strength of components by preserving the grain flow of the material they are made of. Drawing can then be followed by a thermal or surface treatment in line with the customer’s needs.

Chamfering

Chamfering involves removing a sharp edge at the end of a part or creating pyramidal tips, commonly used in electronic connector systems, for example.

Folding / Bending / Rolling

Bending, a technology that accompanies drawing, is used to form a metal strip into three dimensions to give it the geometry required, and is also used for perfectly regular revolving forms such as cones, cylinders and ogives.

Debossing

We can add a debossing stage to the manufacturing process to engrave references and other markers or to make conical or diamond type ridges and markings. The fineness of the engraving can be adjusted to the customer’s requirements.

Small components assembly

Our production process can produce up to three different parts simultaneously with a final riveting or crimping assembly.