AXFIL work

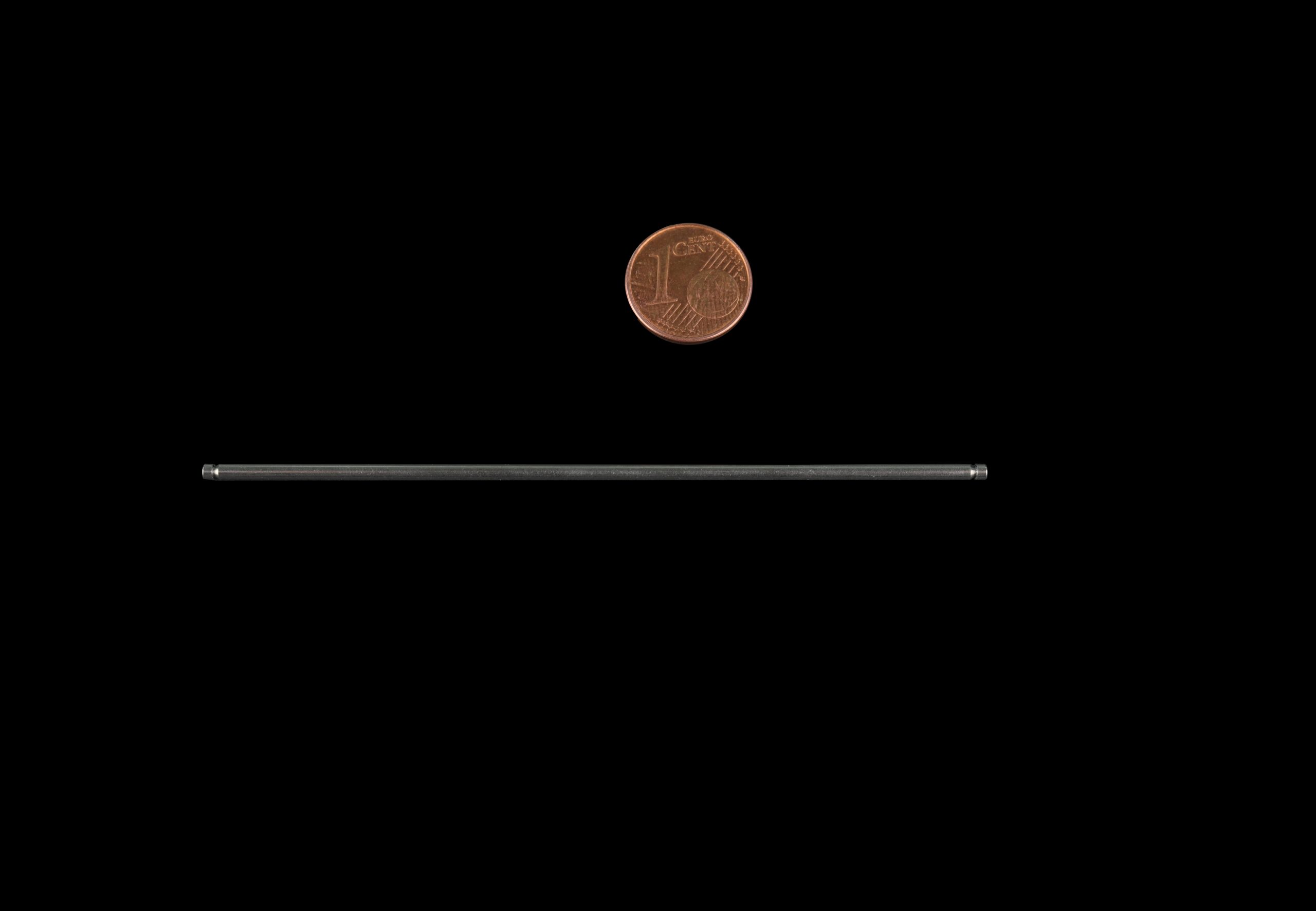

Stainless steel grooved pin

Function

Pistons for closing the cylinder mechanisms of drawers

Technical requirements

Length (±0.10 mm) and straightness precision < 0.10 mm, machining tolerance ±0.05 mm with no material protuberance, roughness < 0.2 µm, diameter precision ±6µm

These requirements meet a combination of precise specifications for geometric precision, high mechanical resistance and a completely smooth surface condition, ensuring the mechanical and hermetic performance of the cylinder throughout the mechanism’s useful life.

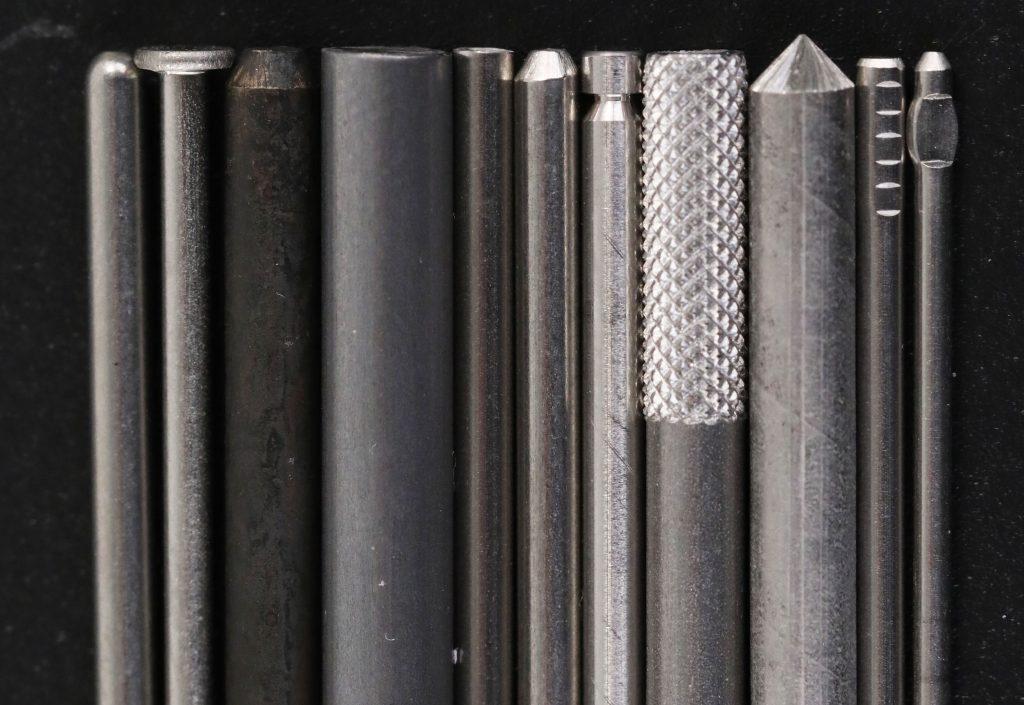

A systematic inspection of the stainless steel wire upon reception allows us to check the dimensions (standard precision +/- 6 µm, tighter tolerances on request), the mechanical characteristics (high or low-resistance steel) and the surface condition. Wire straightening is the first stage in the manufacturing process. The aim is to achieve perfect straightness, which requires constant monitoring throughout the production process to adjust the machine settings in real time to accommodate for the tiniest variations in the steel’s mechanical characteristics. This is done for the entire 20 kms of wire on a reel. Precision cutting, the second stage in the process, is Axfil’s trademark activity. We have expert knowledge of the settings needed to make a cut that is perfectly straight, clean and devoid of burring, with a precision generally to within ±0.10 mm. Making all of our own machinery and tooling in-house, the quality of our work is unrivalled on the market.

Axfil then shapes the end sections in line with customer requirements: straight, chamfered, rounded, ridged, stamped, headed (circular, conical, etc.), using its fleet of constantly maintained, state-of-the-art machinery (heading machine, laser head, press and turning lathe). Drawing on the experience of our design team and operators, we can design, manufacture and fine-tune precision tools that will deliver the geometric precision and repeatability of end sections.

Mechanical polishing, the last stage in the process, produces an Ra roughness below the standard 0.2 µm and even lower if requested. This ensures the durability of our joints and hermetic performance of our pistons. Tribofinishing is a delicate process and for each operation a perfect balance must be found between the vibratory profile of the tank, the type and quantity of the polishing medium, the additives and the polishing time.

Mechanical polishing, the last stage in the process, produces an Ra roughness below the standard 0.2 µm and even lower if requested. This ensures the durability of our joints and hermetic performance of our pistons. Tribofinishing is a delicate process and for each operation a perfect balance must be found between the vibratory profile of the tank, the type and quantity of the polishing medium, the additives and the polishing time.

Materials

Stainless Steel 1.4305